Little Known Facts About Copper Foil.

Some Known Questions About Copper Foil.

Table of Contents10 Simple Techniques For Copper FoilIndicators on Copper Foil You Need To KnowSome Of Copper FoilCopper Foil - TruthsAn Unbiased View of Copper FoilThe Main Principles Of Copper Foil Facts About Copper Foil UncoveredCopper Foil for DummiesAll about Copper Foil

When you copper aluminum foil tarnished glass whole lots of inquiries come up that you weren't instructed just how to deal with. Scroll down to find a whole checklist of responses to aid improve your tarnished glass copper hindering.There are structural as well as visual options to be made. If you go for the copper foil you'll be spot on. 3/16" 1/4" foil works well for a lot of conventional copper aluminum foil discolored glass items. If you have a wider overlap you might find that the size of the solder is as well vast when you begin assembling the item with each other.

Facts About Copper Foil Uncovered

The smart Trick of Copper Foil That Nobody is Discussing

The rolls fit flawlessly as well as when the lid is protected in position, it helps maintain the aluminum foil. Beginning foiling far from the perimeter of a piece When you copper foil stained glass it's ideal to start hindering away from the outdoors side as this makes for more powerful attachment. This is because the foil isn't joined on the outside side where is is most likely to come loose.

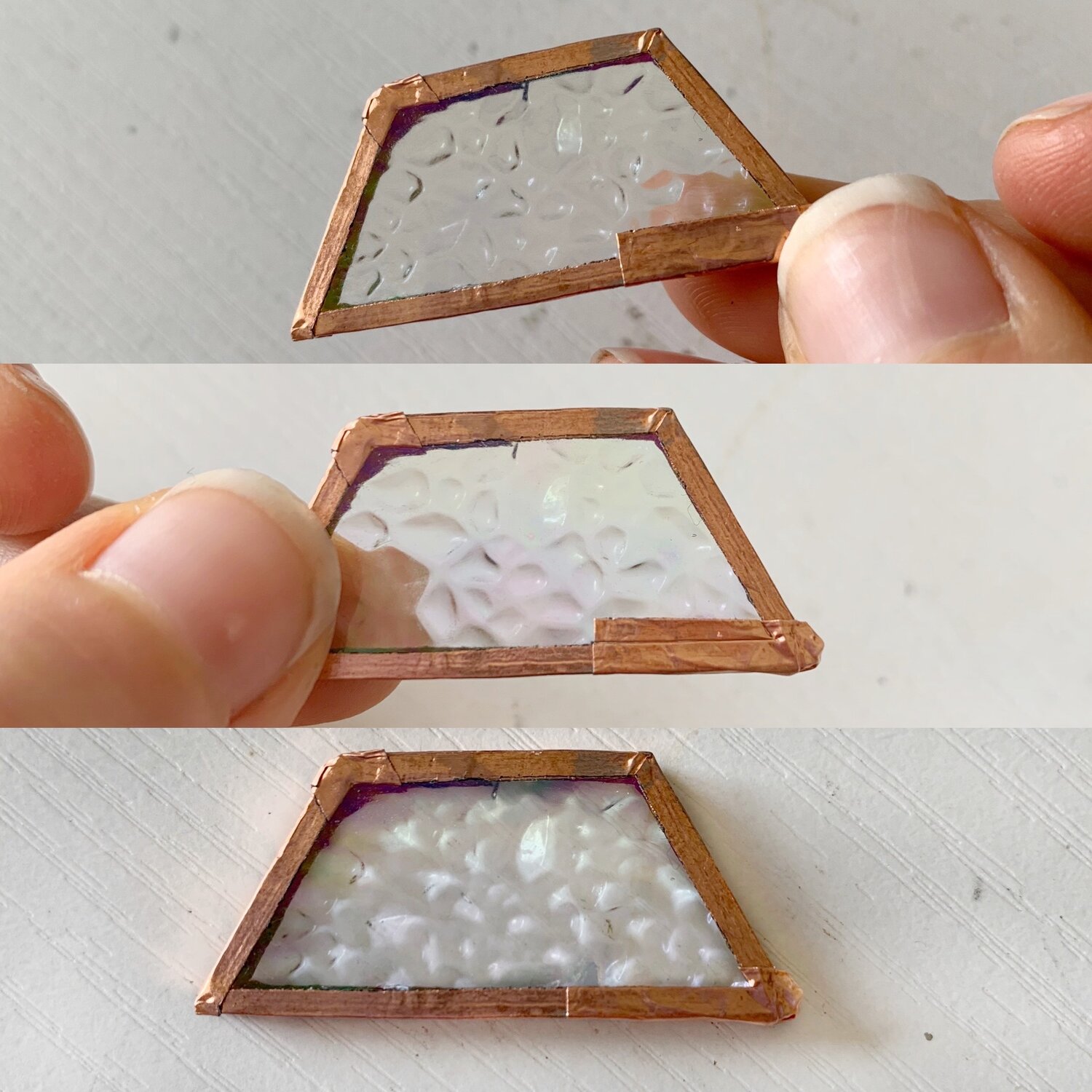

Do you know just how to copper aluminum foil discolored glass that is heavily textured? If you have actually attempted this you'll recognize that the aluminum foil breaks as you attempt to go from high to low. Despite having superficial distinctive glass (ripples) the aluminum foil sometimes damages as it goes across the surges instead of nicely contouring to it.

Some Known Details About Copper Foil

Use a cork for kinking distinctive glass as it is softer and supplies pressure while minimizing tearing. It cleans the aluminum foil too!

Better still, you can make use of a to eliminate the hefty appearance on the glass before hindering. Usage lined paper to help centre the copper foil When you copper foil tarnished glass by hand it can be tough to centre the aluminum foil.

Copper Foil Things To Know Before You Get This

Usage lined paper as an overview! This is a fascinating pop over to these guys question and also one I get asked A WHOLE LOT. My solution could save check out here you hrs of time grinding as well as cleaning. When you copper aluminum foil discolored glass you do not have to have a rough surface area for the foil to stay with.

You can simply deaden the sharp sides off with a damp scythe stone to prevent cutting on your own and also to protect against sharp edges cutting the aluminum foil. Occasionally when you copper aluminum foil stained glass the aluminum foil comes away from the edge.

All about Copper Foil

If you solder as well gradually or look at the solder consistently the aluminum foil adhesive thaws as well as ends up being unstuck. It deserves bearing in mind that the adhesive is there to hold the aluminum foil in area till it's soldered. It doesn't offer to keep it on as soon as it's been warmed. Attempt increasing the width of the outside aluminum foil a little bit too.

If you tin the sides as opposed to developing a beaded side. "Tinning" implies covering them with a thin finish of solder. "Beading" is a rounded edge of solder that 'clings' to the side of the discolored glass and also is much more powerful. I have a video clip on exactly how to do a beaded edge on this page. Be mild when cleaning and polishing.

The Best Guide To Copper Foil

There are a lot more solutions about copper foil not sticking right here.

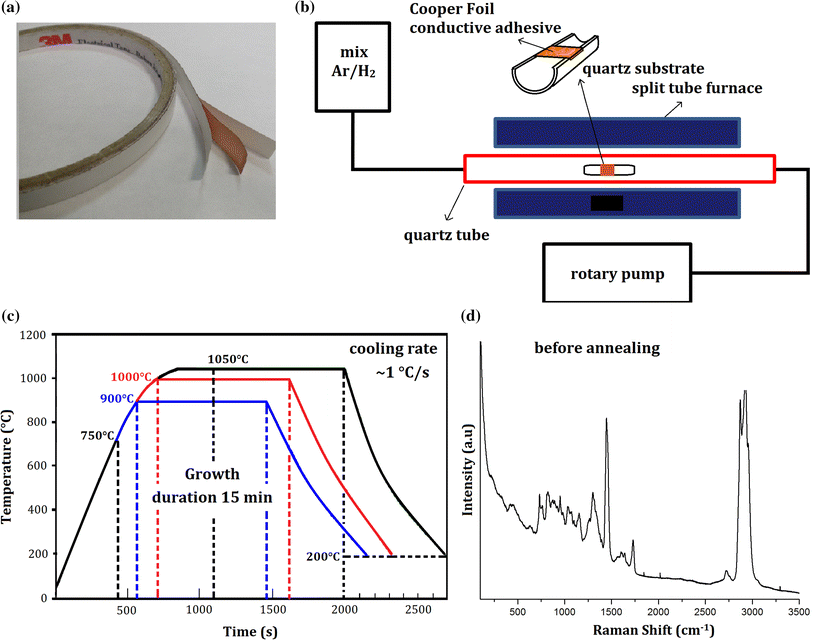

Electrical wiring demand is one of the most important vehicle drivers for electronic bundle selection. The Semiconductor Market Association (SIA) (Sematech) releases a paper regularly to suggest the market of the existing and future electrical wiring need for a variety of product directory kinds. Table 1 reveals parts of the table that was published in 1999 (copper foil).

Things about Copper Foil

Reduced I/O are in hand held products that compromise on performance to achieve their smaller size. These I/O values are leading edge applications with the largest variety of I/Os. Common applications have much lower demand however gradually will reach the leading side demands, which are 510 years in advance of the normal item.

The other item of the I/O equation is the dimension of the chip. This is primarily a function of how numerous circuits are being used by the application.

4 Easy Facts About Copper Foil Explained

In this strategy, a gold or light weight aluminum wire is adhered to a pad on the chip and after that looped to a pad on the chip service provider, which is the base for the module. A typical chip to substratum connection making use of cable bond is kept in mind in Fig. 1. With discrete cords, their placement can not be as well close or the wires will certainly touch each other.